Have you ever felt that pang of worry when your diesel engine sputtered to life, its familiar rumble replaced by a hesitant cough? Have you ever wondered what lurks beneath the hood in those intricate systems that power our vehicles and machines? Today, we embark on a journey into the heart of diesel technology: the injection pump. Unveiling its secrets, we’ll explore the delicate art of desmontaje de bomba de inyección diesel – the process of dismantling and understanding these vital components.

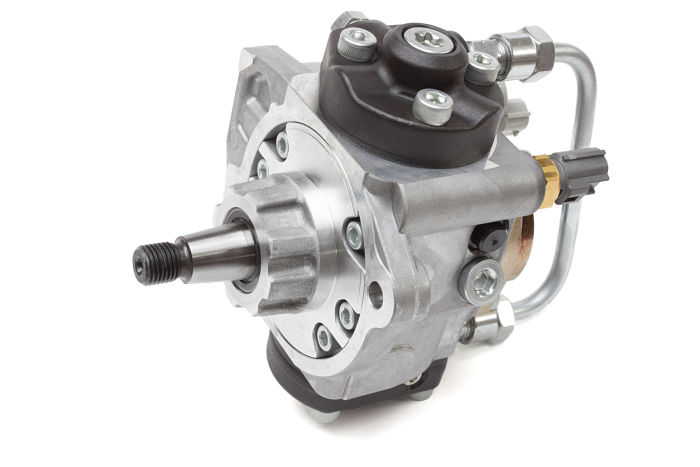

Image: qs-center.net

While the phrase might seem daunting, the truth is that understanding the intricacies of these pumps is paramount to ensuring the smooth operation of any diesel engine. Whether you’re a seasoned mechanic or a curious enthusiast, this guide will equip you with the knowledge to maintain and troubleshoot your equipment, empowering you to take control of your diesel engine’s performance.

Delving Deeper: A Look Inside the Diesel Injection Pump

The diesel injection pump, often referred to as a “fuel pump,” plays a pivotal role in the combustion process. It’s not just a basic pump, but a precise and intricate system that measures, regulates, and delivers fuel under high pressure to the engine’s cylinders. These pumps are the heart of diesel engines, responsible for injecting the fuel at the precise time and amount required for efficient combustion.

There are several types of diesel injection pumps, each with its own unique features and levels of complexity. Some of the most common types include:

- In-line pumps: These pumps are typically mounted directly on the engine block and feature separate plungers and delivery valves for each cylinder.

- Distributor pumps: These pumps utilize a rotating distributor to deliver fuel to each cylinder.

- Common rail pumps: These are the modern and more efficient pumps that provide high-pressure fuel to a common rail system that then distributes it to the injectors.

Understanding the Components of the Diesel Injection Pump

Every diesel injection pump, regardless of its type, is comprised of several crucial components. These are the key players in the meticulous process of fuel delivery:

- Pump body: The housing of the pump, often made of cast iron or aluminum, which encloses all the vital components.

- Plungers: These are the heart of the pump, their movement controlled by the camshaft, which creates pressure by drawing fuel into the pump and moving it through the delivery valves.

- Delivery valves: These valves control the timing and amount of fuel injected into each cylinder.

- Fuel lines: The pipes that carry the fuel from the pump to the injectors.

- Governor: This component regulates the fuel delivery based on engine speed and load demands.

- Fuel filter: Filters out impurities in the fuel, ensuring the pump is protected from damage.

Demystifying the Art of Dismantling: A Step-by-Step Guide

Desmontaje de bomba de inyección diesel, while seemingly complex, is a task that can be mastered with patience and a clear understanding of the components. Here’s a basic guide to help you navigate this process safely and effectively:

Preparation is Key:

- Gather your tools: You’ll need a comprehensive set of tools, including wrenches, sockets, screwdrivers, pliers, and a torque wrench. Make sure you have the right size tools for the specific pump you’re working on.

- Safety first: Wear protective gear like safety glasses, gloves, and work clothes. The environment can be oily and potentially dangerous.

- Clean work area: Ensure a clean and well-lit space to work. This will help avoid contamination of the delicate pump components.

- Disconnect the fuel lines: Before starting, disconnect the fuel lines leading to and from the pump.

The Dismantle Process:

- Removal: Carefully remove the pump from the engine. If it’s a distributor pump, you might have to remove the governor and housing first.

- Disassembly: Begin by removing the cover plate. For some pumps, you might need to remove external components like the governor or the fuel line connections.

- Plunger & Delivery Valve Removal: Carefully remove each plunger and its accompanying delivery valve. Use proper tools and techniques to avoid damaging these parts.

- Clean thoroughly: Clean every component with a suitable solvent, ensuring all parts are free of dirt, debris, and fuel residue.

- Inspection: Carefully inspect each component for wear, cracks, or any other damage. This will help determine if parts need replacing.

Image: voitures-motos.com

Expert Insights and Actionable Tips for Success

“Remember,” advises veteran mechanic, John, “the most crucial aspect of this process is meticulousness. Every part plays a role in the intricate symphony of fuel delivery. A single misplaced or damaged component can disrupt the entire system.”

Here are a few key tips from experts:

- Consult the service manual: Never embark on this task without referring to the specific service manual for your engine model. It will provide detailed instructions and specifications.

- Professional assistance: For intricate or critical tasks, it’s often wise to seek the help of a qualified mechanic. They possess specialized knowledge and tools.

- Spare parts: Have spare parts ready before beginning disassembling. This ensures a smooth transition if you encounter worn-out components.

Desmontaje De Bomba De Inyección Diesel

A Journey of Understanding: Your Next Steps

By understanding the intricacies of desmontaje de bomba de inyección diesel and armed with the guidance from this article, you are equipped with the knowledge and tools to ensure the longevity and performance of your diesel engine. Whether you’re a seasoned mechanic, a curious enthusiast, or simply someone who understands the importance of their vehicle, this guide empowers you to take control of your diesel engine’s health.

Remember, knowledge is power, and in the world of diesel engines, the ability to understand and maintain your equipment is paramount. So, gear up, consult your service manuals, and embark on the journey of understanding the heart of your diesel engine!