The satisfying roar of a Briggs & Stratton engine powering a lawnmower, generator, or other equipment can be quickly silenced by a faulty ignition coil. This vital component plays a crucial role in igniting the fuel-air mixture by generating a high-voltage spark. But deciphering the intricate wiring diagram of an ignition coil can seem like a daunting task for even the most experienced DIY enthusiast. This comprehensive guide will provide you with a thorough understanding of Briggs & Stratton ignition coil wiring diagrams, helping you troubleshoot issues and restore your equipment’s power.

Image: projectopenletter.com

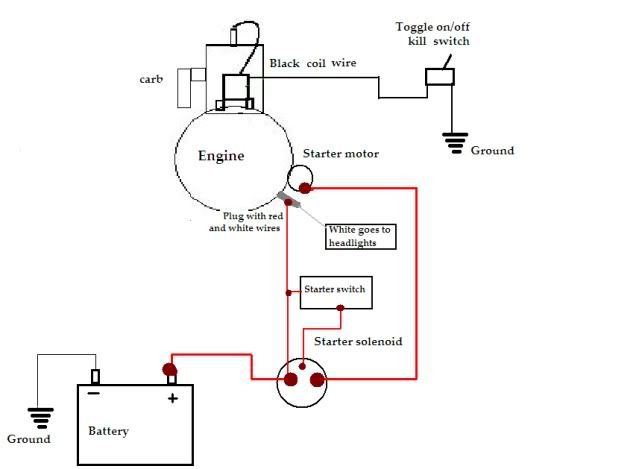

Understanding the wiring diagram is essential for effectively diagnosing and repairing ignition problems. It acts as a roadmap, guiding you through the intricate connections and components that ensure a smooth spark delivery. By interpreting the diagram, you can identify potential issues such as faulty wiring, a defective ignition coil, or broken connections that might be hindering your engine’s performance. This guide will delve into the key elements of the diagram, empowering you to navigate the world of Briggs & Stratton ignition systems with confidence.

Decoding the Wiring Diagram: Understanding the Key Components

The Briggs & Stratton ignition coil wiring diagram serves as a visual representation of the electrical flow from the ignition system to the spark plug, detailing all essential components. This diagram is crucial for understanding the functioning of your engine’s ignition system and can aid in both troubleshooting and repairs.

The Ignition Coil: The Heart of the System

The ignition coil is the core component of the system. It acts as a transformer, converting low-voltage current from the battery into a high-voltage spark that ignites the fuel-air mixture inside the engine’s combustion chamber. The coil consists of two windings: a primary winding and a secondary winding. The primary winding is connected to the battery and energized by the ignition switch. This energizes a magnetic field in the coil. Once the ignition switch is closed, the primary winding is interrupted, causing the magnetic field to collapse. This collapse induces a high-voltage pulse in the secondary winding, which travels to the spark plug.

The Ignition Module: The Brain of the Operation

The ignition module, also referred to as the control module or electronic ignition module, is the electronic brain of the ignition system. It regulates the timing of the spark and ensures optimal combustion for the engine. The module receives signals from various sensors, including the crankshaft position sensor, and uses these signals to control the firing of the ignition coil. The module dictates the moment the spark is created, ensuring proper timing for the engine to operate efficiently.

Image: diagramqu.blogspot.com

The Spark Plug: Delivering the Spark

The spark plug plays a crucial role in initiating the combustion process. It functions as a bridge between the ignition system and the engine’s cylinder, delivering the high-voltage spark from the ignition coil to the fuel-air mixture. This spark ignites the mixture, creating a controlled explosion that drives the piston. A spark plug consists of two electrodes, a central electrode and a ground electrode, separated by a small gap. The high-voltage current jumps this gap, producing a spark that ignites the combustible mixture within the cylinder.

Understanding the Terminology

Before delving into the intricacies of the wiring diagram, it’s essential to understand some common terminology. These terms will help you navigate the diagram with ease and comprehend the functionality of the components involved.

- Wire Color Codes: Briggs & Stratton utilizes specific color codes for different wires to ensure proper connection and organization. Common color codes include black (ground), red (positive), green (ignition), yellow (tachometer), blue (negative), and brown (alternator). These codes are indicated on the wiring diagram.

- Connector Positions: The diagram will usually illustrate the connectors, such as the ignition coil connector, the ignition module connector, and the spark plug connector. These diagrams provide pin numbers for each connector, helping you identify the correct wire for each terminal.

- Circuit Paths: The diagram showcases the path of electricity from the battery, through the ignition switch, ignition module, ignition coil, and finally to the spark plug. Each circuit path is clearly outlined, helping you trace the flow of electricity and identify potential fault points.

Troubleshooting Common Ignition Problems

Understanding the wiring diagram is crucial for identifying and addressing common ignition issues. By carefully following the circuit paths and identifying the corresponding components, you can effectively pinpoint the source of the problem, whether it be a broken wire, a defective ignition coil, or a faulty module.

No Spark

One of the most common ignition problems is a lack of spark. This can be caused by a variety of factors, including a faulty ignition coil, a broken wire, or a malfunctioning ignition module. To diagnose the issue, start by testing the ignition coil for continuity using a multimeter. If the coil is faulty, replace it. If the coil tests good, check the wiring for any breaks or loose connections. If everything appears to be in order, then the problem may lie with the ignition module. You can test the module for functionality using a specialized ignition module tester.

Weak Spark

A weak spark can also hinder engine performance. It might be caused by a dirty or corroded spark plug, a cracked or worn spark plug wire, or a failing ignition coil. You should start by cleaning the spark plug or replacing it if worn. Check the spark plug wire for cracks or damage. If the problem persists, there could be an issue with the ignition coil. Inspect the coil for any signs of damage, such as cracks or burn marks. If the coil appears faulty, replace it. You should also examine the wires leading to and from the ignition module for any damage.

Engine Not Starting

If your engine is not starting, it could be an ignition problem. Start by checking for spark at the spark plug. Make sure the battery is charged and that all connections are tight and clean. Check for any loose connections. You can test for spark using a spark tester. If the spark plug is not receiving a spark, then you have an ignition system problem. Using the wiring diagram, check the ignition module for signs of damage and the ignition coil for cracks or burns. You should also verify the wiring between the ignition module, coil, and spark plugs.

Expert Advice and Tips

While diagnosing and repairing ignition problems can seem challenging, several tips and tricks can make the process easier and more efficient. Here are some recommendations for those working with Briggs & Stratton ignition coil wiring diagrams:

- Use a Wiring Diagram Specific to Your Engine: Briggs & Stratton manufactures a wide range of engines, and each model has a unique wiring diagram. Using the right diagram tailored to your specific engine model is crucial for accurate troubleshooting and repairs.

- Consult the Owner’s Manual: The owner’s manual for your engine is a valuable resource. It often includes detailed wiring diagrams, as well as instructions for troubleshooting common ignition problems. Having this manual readily accessible can be a lifesaver during repairs.

- Be Patient and Thorough: Troubleshooting ignition problems requires patience and a methodical approach. Carefully follow the wiring diagram, checking each component and connection to ensure everything is in working order. Don’t rush the process, as missing even a small detail can lead to further complications.

- Work in a Safe Environment: When dealing with electrical systems, safety is paramount. Make sure your work area is well-lit and free of clutter. Disconnect the battery before working on any electrical component to prevent accidental shocks. Always handle wires and connections with care.

- Use the Correct Tools: To effectively troubleshoot ignition problems, you’ll need the right tools. A multimeter is essential for testing continuity and voltage. Other helpful tools include a spark tester, wire crimping tool, and a wrench set.

FAQ: Frequently Asked Questions

Here are some frequently asked questions regarding Briggs & Stratton ignition coil wiring diagrams:

Q: Why do ignition coils fail?

A: Ignition coils are susceptible to failure due to various factors, including wear and tear, exposure to moisture, extreme temperatures, and electrical surges. Over time, the internal windings of the coil can become damaged or weakened, leading to reduced spark output or complete failure.

Q: Can I replace an ignition coil myself?

A: Replacing an ignition coil is a relatively straightforward task that can be done by a competent DIY enthusiast. However, it’s essential to have a basic understanding of electrical systems and follow the instructions in your owner’s manual or the instructions accompanying the new ignition coil. If you’re unsure about performing the repair yourself, it’s best to seek assistance from a qualified mechanic.

Q: Should I replace the ignition module if the coil fails?

A: While a failing ignition coil is a common cause of ignition problems, a faulty ignition module can also contribute to issues. However, it’s not always necessary to replace the module if the coil fails. You should always test the module for proper functionality before replacing it. If the coil fails for no apparent reason, it may be advisable to replace the module as a preventative measure.

Briggs And Stratton Ignition Coil Wiring Diagram

Conclusion

Understanding Briggs & Stratton ignition coil wiring diagrams is crucial for anyone who owns equipment powered by these engines. By grasping the basics of the system, identifying key components, and following the circuit paths, you can navigate ignition problems with confidence. This guide has provided a comprehensive overview of Briggs & Stratton ignition coil wiring diagrams, encompassing troubleshooting advice, expert tips, and a handy FAQ. Let us know if this article was helpful by leaving a comment below!

Are you interested in learning more about Briggs & Stratton engines or other related topics? Let us know in the comments!