Imagine a manufacturing plant where every part arrives just in time for assembly, eliminating the need for large, expensive inventory holding. This is the essence of JIT systems, a revolutionary approach to production that has transformed the manufacturing landscape. While the concept of “just-in-time” might seem simple, its implications are far-reaching, impacting everything from supply chain dynamics to overall efficiency.

Image: www.chegg.com

JIT systems go beyond a mere inventory management tactic—they demand a holistic transformation of a company’s internal processes and external relationships. This approach requires a tightrope walk between minimizing waste and ensuring on-time deliveries. It’s about streamlining operations, optimizing production flows, and fostering strong partnerships with suppliers. In this article, we’ll delve deep into the world of JIT systems, exploring its defining characteristics, exploring its benefits, highlighting its challenges, and offering insights into its future trajectory.

Understanding the Core Principles of JIT Systems

JIT systems, also known as Just-in-Time production or lean manufacturing, are a production strategy that aims to minimize waste and optimize efficiency by producing goods only when they are needed. At its core, JIT hinges on the following key principles:

- Pull System: Production is triggered by actual customer demand rather than pre-determined schedules. This eliminates the risk of overproduction and minimizes waste by ensuring that only the needed quantity is produced.

- Zero Inventory: JIT strives for minimal inventory levels, reducing storage costs and minimizing the risk of obsolescence. The ideal scenario is to have parts arrive just in time for production and finished products shipped immediately to customers.

- Continuous Improvement: JIT emphasizes a culture of continuous improvement, relentlessly seeking ways to eliminate waste and enhance efficiency. This involves a constant cycle of analysis, problem-solving, and refinement.

- Total Quality Management: JIT systems are underpinned by a commitment to quality, striving for zero defects in production. This ensures that products meet customer expectations, minimizing rework and scrap.

- Flexible Workforce: JIT systems often require a flexible workforce capable of adapting to changing production needs. This can involve training workers to be multi-skilled and cross-trained, allowing for quick response to variations in demand.

These principles work in concert to create a highly efficient and responsive production system. By eliminating excess inventory, JIT systems free up valuable capital and reduce warehousing costs. Furthermore, by focusing on continuous improvement, companies can continuously optimize their processes, leading to higher productivity and lower costs.

Challenges & Benefits of Implementing JIT Systems

Challenges

While the benefits of JIT systems are widely acknowledged, their implementation can pose significant challenges:

- Supplier Dependence: JIT relies heavily on reliable suppliers who can deliver the required parts exactly when needed. Delays or disruptions in the supply chain can quickly halt production, leading to costly downtime.

- Inventory Volatility: Keeping inventory at a minimum leaves little room for error. Fluctuations in demand can quickly deplete inventory, leading to production delays and lost sales.

- Process Integration: Successfully implementing JIT requires a comprehensive understanding of all internal processes and strong collaboration across different departments.

- Initial Investment: Implementing JIT systems can involve substantial upfront investments in new technology, training, and process improvements.

- Flexibility and Adaptability: JIT systems need to be adaptable to changing market conditions and customer demand patterns. This may require investments in flexible manufacturing technologies and a workforce that is highly versatile.

Image: www.slideshare.net

Benefits

Despite these challenges, JIT systems offer several compelling benefits that can significantly improve a company’s bottom line:

- Reduced Inventory Costs: By keeping inventory levels low, JIT systems can significantly reduce storage, handling, and obsolescence costs. This frees up capital for strategic investments and potentially lowers operating costs.

- Increased Productivity: JIT systems encourage a focus on efficiency and continuous improvement. This can lead to shorter production cycles, reduced waste, and higher overall productivity.

- Improved Quality: JIT emphasizes quality control, leading to reduced defects and scrap rates. This enhances customer satisfaction and reduces rework costs.

- Enhanced Responsiveness: JIT systems are highly responsive to customer demand. They allow companies to quickly adjust production to meet fluctuations in demand, leading to shorter lead times and improved customer satisfaction.

- Stronger Supplier Relationships: JIT systems require strong partnerships with suppliers. This can lead to a more collaborative relationship, with suppliers working closely with companies to ensure timely and reliable deliveries.

Modern Trends & Developments in JIT Systems

JIT systems are constantly evolving in response to changing business demands and technological advancements. Here are some noteworthy trends and developments:

- Digital Transformation: Technology is playing an increasingly important role in JIT systems. Digital tools such as ERP systems, cloud-based platforms, and predictive analytics enable better inventory forecasting, supply chain visibility, and real-time process optimization.

- Agile Manufacturing: JIT principles are being integrated with agile manufacturing concepts, allowing organizations to respond quickly to changing customer needs and market dynamics. Agile manufacturing focuses on flexibility, customer collaboration, and continuous improvement.

- Supply Chain Resilience: The COVID-19 pandemic highlighted the need for more resilient supply chains. Companies are looking at ways to diversify their suppliers, implement contingency plans, and improve their ability to withstand disruptions.

- Sustainability Considerations: JIT systems are increasingly incorporating sustainable practices, such as reducing waste, minimizing transportation, and using eco-friendly materials. This aligns with the growing trend towards environmentally conscious business practices.

- Customization and Mass Personalization: As consumers increasingly demand personalized products, JIT systems are evolving to accommodate custom orders and mass personalization. This requires greater flexibility and agility in production processes.

These trends suggest that JIT systems are becoming more sophisticated and adaptable, leveraging technology and evolving business practices to optimize production and enhance responsiveness. This adaptability is essential for companies to remain competitive in a constantly evolving landscape.

Tips & Expert Advice for Implementing JIT Systems

Successfully implementing JIT systems requires careful planning and execution. Here are some tips and expert advice that can help:

- Start Small: Don’t try to implement JIT across all processes at once. Start with a small, manageable project and gradually scale up as you gain experience.

- Build Strong Supplier Relationships: Close collaboration with suppliers is critical. Work with them to establish clear communication channels, set realistic delivery expectations, and develop a culture of mutual trust.

- Invest in Process Improvements: Continuous improvement is key to successful JIT implementation. Identify areas for improvement, invest in training, and use data-driven decision-making to optimize processes.

- Focus on Quality: A commitment to quality is essential to prevent rework and scrap. Implement robust quality control processes and train workers to identify and address quality issues.

- Embrace Flexibility: JIT systems require a flexible workforce and adaptable processes, capable of responding to fluctuations in demand and changing market conditions. It can involve cross-training employees and investing in flexible manufacturing technologies.

Implementing JIT systems is a journey, not a destination. It requires ongoing commitment, a willingness to experiment, and a relentless focus on improvement. By embracing these principles, companies can optimize their production processes, reduce costs, and enhance their ability to meet customer needs in a dynamic market environment.

FAQ on JIT Systems

What are the different types of JIT systems?

There are various types of JIT systems depending on the specific needs of a company and its industry. Some common examples include:

- Traditional JIT: The classic JIT system with a focus on minimizing inventory and maximizing efficiency.

- Канбан JIT: Utilizes a system of cards or signals to trigger production based on actual demand.

- Material Requirements Planning (MRP): Uses software to plan and track materials, ensuring they are available when needed.

- Manufacturing Resource Planning (MRP II): Extends MRP to include other aspects of the manufacturing process such as production scheduling, capacity planning, and inventory management.

- Enterprise Resource Planning (ERP): A comprehensive system that integrates all aspects of business operations, including manufacturing, finance, and human resources. It can be a powerful tool for implementing and managing JIT systems.

What are the key performance indicators (KPIs) for JIT systems?

Several KPIs can be used to measure the performance of JIT systems. These include:

- Inventory Turnover Rate: Measures how quickly inventory is sold and replaced. Higher turnover rates indicate a more efficient inventory management system.

- Lead Time: Measures the time it takes to produce a product from order to delivery. Shorter lead times are indicative of a more responsive production system.

- Production Efficiency: Measures the ratio of output to input in manufacturing. Higher efficiency rates indicate a less wasteful production process.

- Defect Rate: Measures the number of defective products produced. Lower defect rates indicate better quality control and less rework.

- Customer Satisfaction: JIT’s goal is to meet customer needs consistently. Key metrics include on-time delivery rates, order fulfillment rates, and customer feedback about product quality and responsiveness.

Are JIT systems suitable for all industries?

JIT systems are not a one-size-fits-all solution. They are best suited for industries with stable demand, high-quality suppliers, and a focus on continuous improvement.

While they can be effective in various industries, from manufacturing to healthcare, industries with highly volatile demand, long lead times, or complex supply chains may find JIT implementation challenging.

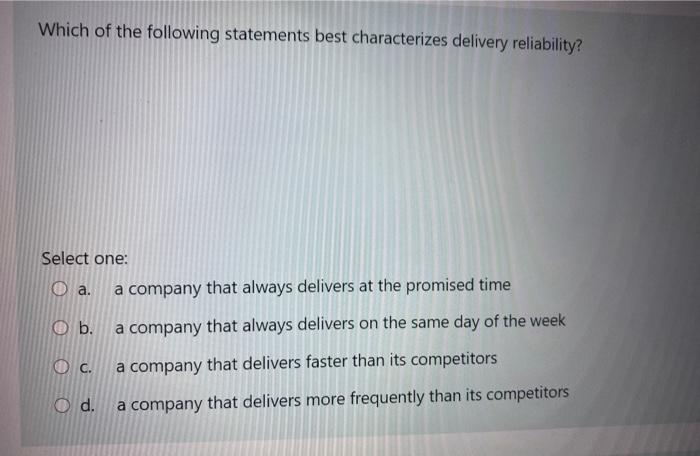

Which Of The Following Best Characterizes Jit Systems

Conclusion

JIT systems, with their emphasis on minimizing waste, optimizing efficiency, and fostering continuous improvement, have become a cornerstone of modern manufacturing. From its origins in lean manufacturing, JIT has evolved to embrace technological advancements and adapt to the ever-changing business landscape. While implementing JIT comes with its own set of challenges, its potential benefits, including reduced costs, enhanced responsiveness, and improved quality, make it a compelling approach for companies seeking to achieve operational excellence.

Are you interested in learning more about the latest trends in JIT systems and how they are impacting different industries? Let us know in the comments below!