Ever wondered how a diesel engine, known for its robust power, can also be environmentally friendly? The answer lies in the complex system of aftertreatment technologies, with Selective Catalytic Reduction (SCR) playing a starring role. This article delves into the fascinating world of Aftertreatment 1 SCR conversion efficiency in Cummins engines, a crucial factor in reducing harmful emissions and ensuring cleaner air.

Image: www.equipmentworld.com

Whether you’re a seasoned truck driver, an emissions compliance expert, or simply curious about the technology powering our modern vehicles, understanding SCR efficiency is key. This technology is at the heart of modern diesel emissions control, and its effectiveness directly impacts air quality and the overall performance of diesel engines. Join us as we unravel the intricacies of SCR and its vital role in Cummins engines.

Understanding Aftertreatment 1 SCR: A Closer Look

Before we dive into the specifics of conversion efficiency, let’s define what Aftertreatment 1 SCR is and why it’s so important.

What is Aftertreatment 1 SCR?

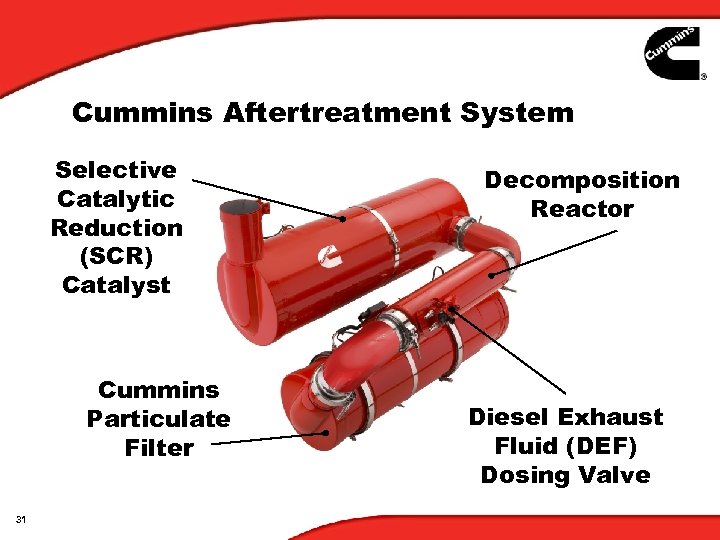

Aftertreatment 1 SCR refers to the first stage of the Selective Catalytic Reduction process in a Cummins engine’s emissions system. This crucial stage involves injecting a urea-based solution, usually Diesel Exhaust Fluid (DEF), into the exhaust stream. DEF, when heated, breaks down into ammonia, a key component in the SCR process.

Why Is SCR Conversion Efficiency So Important?

The effectiveness of this process is measured by SCR conversion efficiency, which represents the percentage of nitrogen oxides (NOx) converted into harmless nitrogen gas by the SCR system. High conversion efficiency translates to significantly reduced NOx emissions, contributing to cleaner air, better fuel economy, and compliance with stringent environmental regulations.

Image: present5.com

Factors Affecting Aftertreatment 1 SCR Conversion Efficiency

SCR conversion efficiency is a dynamic process influenced by several factors. Understanding these factors is crucial for maximizing SCR effectiveness and maintaining optimal engine performance.

1. Diesel Exhaust Fluid (DEF) Quality

The quality of DEF plays a pivotal role in SCR conversion efficiency. Using DEF that meets the required specifications is essential for proper ammonia production and subsequent NOx reduction. Low-quality DEF can lead to decreased conversion efficiency, potentially resulting in increased emissions and engine performance issues.

2. SCR Catalyst Condition

The SCR catalyst, a vital component in the SCR system, is responsible for facilitating the chemical reaction that converts NOx into nitrogen gas. The catalyst’s condition and lifespan directly impact its ability to perform this crucial function. A clogged or aging catalyst can hinder NOx reduction, decreasing conversion efficiency.

3. Engine Operating Conditions

Engine operating conditions, such as engine speed, load, and exhaust gas temperature, significantly influence SCR conversion efficiency. Optimal operating conditions are essential for efficient ammonia production and NOx reduction. Fluctuating operating conditions can impact catalyst performance and SCR efficiency.

4. Engine Control Unit (ECU) Calibration

The Engine Control Unit (ECU) plays a crucial role in optimizing SCR system performance. Proper ECU calibration ensures accurate DEF injection, optimal catalyst temperature, and precise control over the SCR system. Out-of-date or misaligned ECU calibration can negatively affect SCR conversion efficiency.

Optimizing Aftertreatment 1 SCR Conversion Efficiency

While SCR technology is incredibly effective, maximizing its performance requires proactive measures and consistent maintenance.

1. Regular DEF Maintenance

Regularly checking and topping up DEF levels is crucial for ensuring a consistent supply of the critical ammonia solution. Low DEF levels can severely impact SCR conversion efficiency, leading to increased emissions.

2. SCR Catalyst Monitoring & Replacement

Monitoring SCR catalyst performance through periodic inspections and diagnostic tests allows for early detection of any degradation or clogging. Replacing the catalyst at the recommended intervals ensures optimal SCR efficiency and performance.

3. Engine Tuning & Calibration

Ensuring the ECU is properly calibrated and updated is crucial for optimal SCR performance. Regular ECU tuning and calibration ensure accurate DEF injection and efficient engine operation, maximizing SCR conversion efficiency.

4. Utilizing Advanced Diagnostic Tools

Modern diagnostic tools offer valuable insights into the health and performance of the SCR system. These tools allow technicians to identify potential issues, assess SCR conversion efficiency, and make necessary adjustments to maintain optimal performance.

The Future of Aftertreatment 1 SCR in Cummins Engines

As environmental regulations continue to tighten, the demand for more efficient and reliable SCR technologies will only increase. Cummins is at the forefront of innovation, constantly developing and refining its SCR systems to meet these demands.

1. Next-Generation SCR Catalysts

Research and development are focused on producing more durable and efficient SCR catalysts. Advanced materials and optimized catalyst designs are being explored to enhance NOx reduction capabilities and extend catalyst lifespan.

2. Improved DEF Management Systems

Efforts are being made to optimize DEF management systems, including more accurate DEF level sensors, improved DEF injection mechanisms, and improved DEF storage and handling solutions. These advancements will contribute to greater efficiency and reduce the risk of DEF-related issues.

3. Integration with Advanced Engine Control Systems

Cummins is exploring the integration of SCR systems with advanced engine control systems, allowing for real-time monitoring, adaptation, and optimization of SCR performance. This integration will enable more accurate DEF injection strategies, enhanced catalyst temperature control, and minimized emissions.

Aftertreatment 1 Scr Conversion Efficiency Cummins

The Importance of Aftertreatment 1 SCR Conversion Efficiency

Effective SCR systems are critical for reducing NOx emissions and ensuring cleaner air. Understanding the factors that influence Aftertreatment 1 SCR conversion efficiency is vital for optimizing engine performance and complying with stringent regulations. From DEF quality to catalyst condition, every aspect of the SCR system contributes to its overall effectiveness. By actively monitoring, maintaining, and continuously improving these systems, we can ensure a cleaner tomorrow while continuing to enjoy the power and reliability of Cummins engines.