Imagine yourself in the heart of a bustling city, the frigid air biting through your layers. You enter a cozy building, greeted by a wave of warmth. This comforting feeling, a product of a well-functioning heating system, hinges on one critical component: the low-pressure boiler. These unsung heroes, quietly toiling away in the background, require regular testing to ensure they operate safely and efficiently. But navigating the technical world of low-pressure boiler tests can feel daunting, even for seasoned professionals. That’s where our comprehensive guide, complete with valuable questions and answers, comes in.

Image: www.slideshare.net

Let’s delve deeper into the world of low-pressure boiler tests, unraveling the intricacies and empowering you with the knowledge to confidently tackle any challenge.

Demystifying Low-Pressure Boilers and Their Tests

Before we dive into the testing questions, let’s understand what low-pressure boilers are and why they require regular inspection. They are a type of boiler designed to operate at a pressure below 15 psi, commonly used for heating domestic and smaller industrial spaces. The “low pressure” moniker refers to the water pressure inside the boiler, not the overall heating system pressure.

Low-pressure boilers, while inherently efficient and cost-effective, require meticulous checks for optimal performance and safety. Testing these boilers is not only a regulatory requirement but also a crucial step in preventative maintenance. Regular tests help identify potential issues, from leaks to faulty components, before they escalate into major problems.

Key Questions for Low-Pressure Boiler Testing: Your Comprehensive Guide

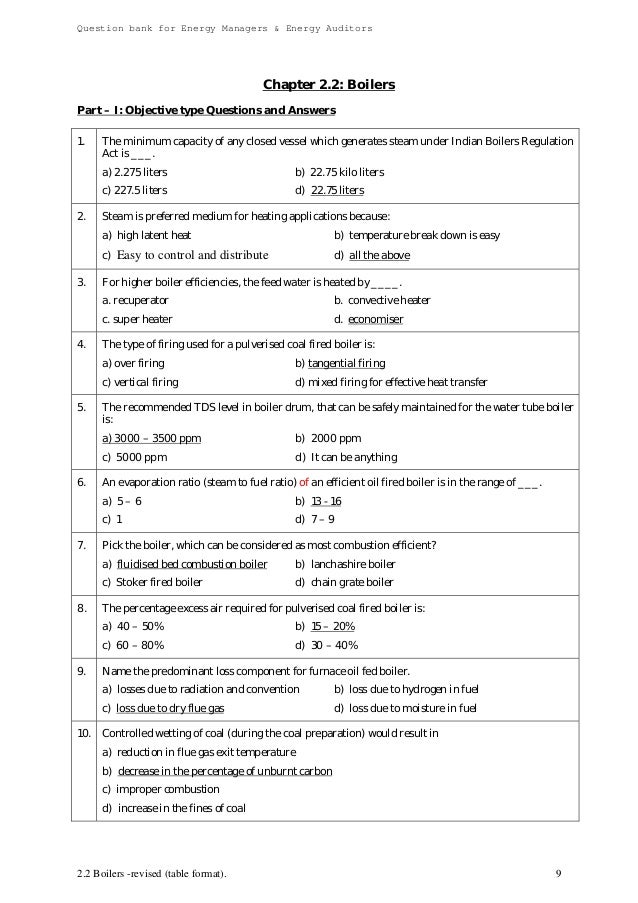

Here’s the breakdown of essential questions and answers covering various aspects of low-pressure boiler testing:

1. What are the Different Types of Boiler Tests?

- Pressure Test: This tests the boiler’s ability to withstand pressure, checking for leaks and structural integrity.

- Water Leak Test: This test specifically focuses on the boiler’s water system, identifying any leaks in pipes, valves, or fittings.

- Burner Performance Test: This measures the boiler’s efficiency by evaluating fuel combustion, flame pattern, and gas pressure.

- Safety Devices Test: This checks the functionality of safety devices like the pressure relief valve, high-limit control, and low-water cutoff.

2. What are the Recommended Frequencies for Boiler Testing?

The frequency of testing varies depending on factors like the age of the boiler, its usage, and local regulations. As a general guideline, consider:

- Annual Tests: Recommended for all low-pressure boilers, ideally conducted before the heating season begins.

- More Frequent Tests: Depending on the boiler’s usage intensity (e.g., in commercial settings), tests might be required every six months.

3. How is a Typical Low-Pressure Boiler Test Conducted?

A certified technician will typically conduct the tests following these steps:

- Visual Inspection: A thorough inspection to check for any visible signs of damage, corrosion, or buildup.

- Pressure Test: The boiler is pressurized with water or air to a specific level, and the technician carefully observes for any leaks.

- Burner Performance Test: The technician examines fuel combustion, flame pattern, and gas pressure to ensure optimal burner performance.

- Safety Devices Test: Each safety device is activated and monitored to ensure proper functionality.

4. What are the Common Problems Found During Low-Pressure Boiler Tests?

Several common issues can arise during testing, including:

- Leaks: Leaks can develop in the boiler’s pressure relief valve, fittings, or pipes, requiring timely repair.

- Corrosion: Build-up of corrosion within the boiler can affect its performance and efficiency.

- Burner Malfunction: A faulty igniter, burner, or gas pressure control can impede efficient combustion.

- Safety Device Failure: A malfunctioning pressure relief valve or high-limit control can pose safety hazards.

5. What are the Essential Documents for Low-Pressure Boiler Testing?

To maintain efficient records and comply with regulations, ensure you have:

- Test Reports: Detailed reports documenting all tests performed, including date, time, results, and any identified issues.

- Boiler Logbook: A logbook for documenting regular maintenance activities, repairs, and performance data.

- User Manual: Keeping the boiler’s user manual is crucial for troubleshooting and understanding its operational guidelines.

Expert Insights and Actionable Tips for Maintaining Low-Pressure Boilers

Let’s hear from experts on how to ensure optimal performance and longevity for your low-pressure boiler:

Expert Tip 1: “Regular maintenance is key to prolonging the life of your low-pressure boiler,” says John, a seasoned heating engineer. “By performing routine checks, you can catch minor issues before they escalate into major problems.”

Expert Tip 2: “Pay close attention to the boiler’s pressure reading,” advises Sarah, a certified plumbing inspector. “Consistent fluctuations can indicate underlying issues that require attention.”

Image: www.youtube.com

Low Pressure Boiler Test Questions And Answers Pdf

Conclusion: Your Path to Safe and Efficient Heating

We hope this detailed guide has provided you with a solid understanding of low-pressure boiler tests, empowering you to confidently address potential maintenance issues. Remember, regular testing is a crucial investment in the safety and efficiency of your heating system. By embracing a proactive approach, you can ensure a warm and comfortable environment for years to come.

Ready to go further? Download our comprehensive PDF guide filled with detailed questions, answers, and practical tips for mastering low-pressure boiler tests!