Imagine a world without trucks roaring down highways, massive ships navigating the ocean, or powerful construction equipment shaping our cities. These machines, and countless others, rely on the robust and efficient power of diesel engines. But what makes them tick? The answer lies in the intricate and fascinating world of the diesel fuel system – a symphony of components working in perfect harmony to deliver the raw power that fuels our modern world.

Image: www.brainkart.com

This comprehensive guide will delve into the inner workings of the diesel fuel system, exploring its components, functions, and the technological breakthroughs that have made it the powerhouse it is today. Whether you’re a diesel engine enthusiast, a mechanic seeking to deepen your knowledge, or simply curious about the technology that powers our world, this exploration will provide valuable insights and a deeper understanding of the diesel fuel system’s vital role.

The Heart of Diesel: A Journey Through the Fuel System

The diesel fuel system is a marvel of engineering, transforming raw fuel into the force that drives our machines. It’s not just a simple pipeline; it’s a meticulously designed system with each component playing a crucial role in maintaining the precise balance required for efficient combustion.

1. Fuel Storage and Supply: The First Steps

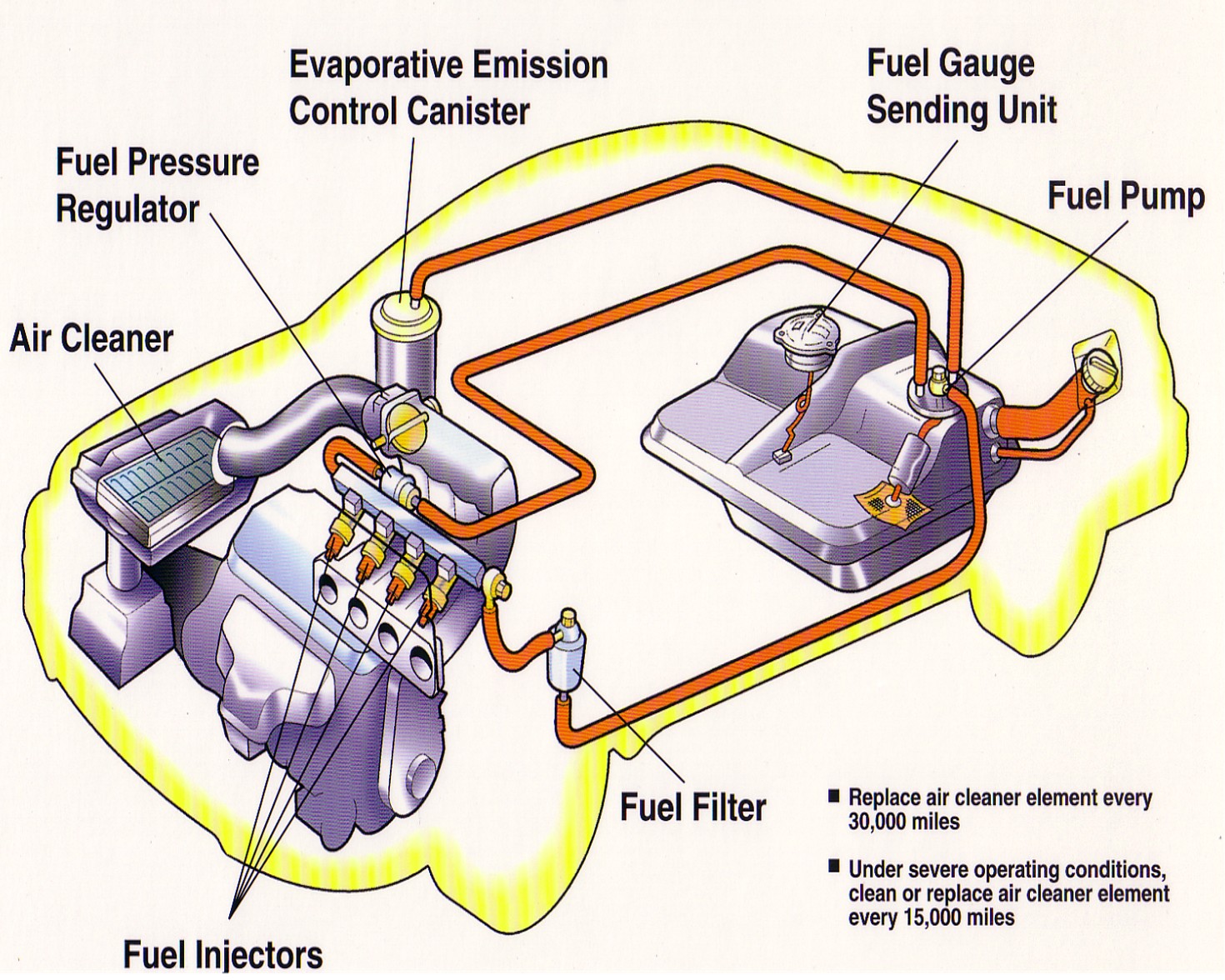

The journey begins with the fuel tank, the heart of the system. It houses the diesel fuel, ensuring a steady supply to the engine. A key element here is the fuel filter, a guardian against contaminants that could clog the engine’s delicate components. This filter acts like a vigilant sentry, removing debris and impurities, ensuring clean fuel reaches the engine.

2. Fuel Delivery: The Precise Movement

Next, the fuel embarks on a carefully orchestrated journey, guided by the fuel pump. This critical component draws fuel from the tank and delivers it to the engine at the right pressure and flow rate. In modern engines, high-pressure fuel pumps are employed, delivering fuel at pressures exceeding thousands of pounds per square inch, enabling efficient combustion even at high engine speeds.

Image: wirefixeric.z19.web.core.windows.net

3. Fuel Injection: The Engine’s Pulse

The fuel then reaches the injection system, the brain center of the diesel engine. Here, the fuel is precisely measured and delivered into the combustion chamber at the optimal time and pressure. Diesel engines rely on the injection pump, a sophisticated device that controls the amount and timing of fuel injection. In newer engines, electronic control units (ECUs) provide real-time adjustments to the injection process based on factors like engine speed and load, maximizing efficiency and minimizing emissions.

4. Combustion: The Power Unleashed

In the combustion chamber, the carefully metered fuel meets the compressed air, igniting a controlled explosion that generates the raw power that drives the engine. The process is unique to diesel engines – the heat generated by the compression of air ignites the fuel, unlike spark-ignition gasoline engines. This ensures efficient combustion, even under demanding conditions.

Unveiling the Secrets of Fuel System Technology

The diesel fuel system has undergone significant advancements, pushing the boundaries of efficiency, power, and environmental impact.

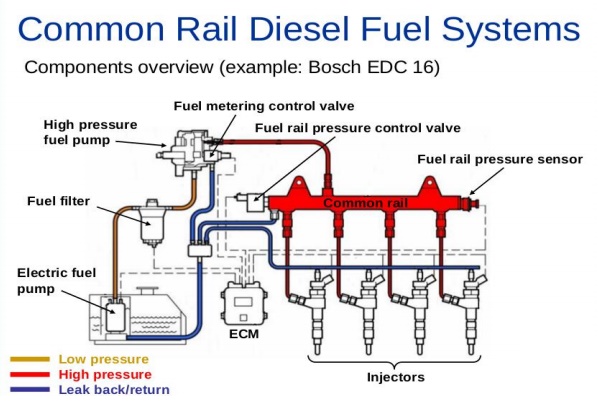

1. The Rise of Common Rail Injection: A New Standard

Common rail fuel injection systems have revolutionized diesel technology, offering exceptional precision and control. This system uses a high-pressure rail to deliver fuel to multiple injectors, allowing for independent control of each injector. This enables precise fuel injection timing and quantity for each cylinder, resulting in improved combustion, reduced emissions, and increased power.

2. Navigating Emissions: The Clean Diesel Revolution

Emissions regulations have driven innovation in diesel fuel systems, leading to the development of technologies like exhaust gas recirculation (EGR) and selective catalytic reduction (SCR). EGR recirculates a portion of the exhaust gases back into the combustion chamber, reducing NOx emissions. SCR systems utilize a catalyst to convert NOx emissions into harmless nitrogen and water vapor.

3. Electronic Control: The Future of Fuel Systems

Electronic control units (ECUs) have transformed the diesel fuel system, enabling real-time adjustments to fuel injection, engine timing, and emissions control. This technology allows the engine to operate at peak efficiency under various conditions, adapting to changes in load, speed, and ambient temperature.

Mastering the Diesel System: Practical Advice and Insights

Understanding the diesel fuel system goes beyond theory; it’s about harnessing its power and ensuring its longevity.

1. Fuel Quality: The Foundation of Performance

The quality of diesel fuel significantly impacts the engine’s performance and lifespan. Using clean, high-quality fuel is essential. Ensure the fuel tank is free from contamination and water, and consider using fuel additives to improve lubricity, prevent rust, and enhance combustion.

2. Regular Maintenance: The Key to Longevity

Regular maintenance is critical to keeping your diesel fuel system in optimal condition. This includes:

- Fuel Filter Replacements: Replace the fuel filter as recommended by the manufacturer to prevent clogging and ensure clean fuel delivery.

- Injection System Service: Service the injection system regularly to ensure proper injection timing, pressure, and overall performance.

- Fuel Pump Checks: Monitor the fuel pump’s performance and address any signs of malfunction promptly.

3. Listen to Your Engine: Recognizing Early Warning Signs

Pay close attention to your engine’s behavior and be aware of any changes that might indicate issues with the fuel system. Common signs include:

- Stalling or Difficulty Starting: This could be a sign of fuel delivery problems, clogged filters, or a failing fuel pump.

- Rough Idling or Poor Acceleration: These problems could stem from irregular fuel injection, clogged injectors, or air leaks in the fuel system.

- Increased Smoke Emission: Excessive smoke can indicate issues with fuel injection timing, air-to-fuel ratios, or clogged injectors.

Fuel System Of Diesel Engine Pdf

https://youtube.com/watch?v=RFL8WOPKAxc

The Power of Knowledge: Embracing the Diesel Future

The diesel fuel system is a testament to human ingenuity, harnessing the power of combustion to fuel our world. As we continue to push the boundaries of efficiency and sustainability, understanding the diesel fuel system is more critical than ever. This guide has provided a glimpse into its intricate workings, empowering you with knowledge to navigate the world of diesel technology.

Keep exploring, keep learning, and let the power of diesel propel you forward!