Ever since I started woodworking, I’ve been fascinated by the intricate mechanics of tools. There’s a certain elegance in seeing a simple band saw slice through wood with precision and power. But when things go wrong, and the saw starts behaving erratically, the beauty turns into frustration. That’s when understanding the band saw parts diagram becomes crucial. This guide delves into the anatomy of Central Machinery band saws, helping you understand each component and how they work together.

Image: pressbooks.bccampus.ca

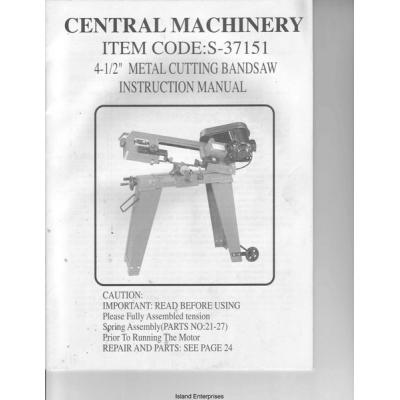

Central Machinery offers a range of band saws, popular for their affordability and performance. Whether you’re a hobbyist or a professional, knowing your band saw inside and out empowers you to maintain, troubleshoot, and even upgrade your machine. Let’s dive into the world of Central Machinery band saw parts.

The Anatomy of a Central Machinery Band Saw

The Cutting Edge: The Blade

The band saw blade is the heart of the machine. It’s an endless loop of toothed steel that rotates continuously, cutting through wood or other materials. The blade’s teeth are carefully designed to create a clean and precise cut. Understanding the blade’s properties like its width, thickness, and tooth pitch is vital for selecting the right blade for your project.

Guiding the Path: The Wheels and Bearings

The band saw blade runs between two large wheels, the upper wheel and the lower wheel. These wheels are supported by bearings, ensuring smooth and stable movement of the blade. The wheels are typically made of cast iron or aluminum and are designed to withstand the constant pressure and friction of the blade. You can find a range of upper wheel designs, from simple cast iron wheels to wheels with adjustable tensioning mechanisms to accommodate different blade thicknesses.

Image: aero-stuff.com

Holding the Wood Securely: The Table and Fence

The table provides a stable platform for supporting the workpiece. It is typically made of cast iron for durability and rigidity. The fence, a guide that helps you make straight cuts, runs parallel to the blade. It can be adjusted for different cutting depths and angles. You can also find models with a miter gauge that allows you to make precise angled cuts.

Powering the Engine: The Motor and Belt

The motor drives the band saw, providing the power to turn the blade. The motor can be either AC or DC depending on the model. A belt connects the motor to the wheels, transmitting power from the motor to the blade. The belt size and configuration vary depending on the model, but they all serve the same purpose – to efficiently transfer power from the motor to the wheels.

Keeping it Smooth: The Guides and Tensioning Mechanisms

The guides keep the blade running straight and prevent it from wandering, ensuring a clean cut. There are typically two or more guides, one directly above the table and another near the upper wheel. The tensioning mechanisms are essential for maintaining the proper tension on the blade, preventing it from breaking or sagging. Proper tension is crucial for ensuring a smooth and accurate cut.

Central Machinery Band Saw Parts: Upgrades and Maintenance

Understanding the various parts of your Central Machinery band saw allows you to customize and improve its performance. Upgrading your blade with a higher tooth count blade can offer smoother cuts, but remember to adjust the guide alignment to accommodate the change. Investing in a dust collection system can keep your workspace clean and prolong the life of your saw. Regularly cleaning the saw, lubricating the bearings, and checking the blade tension ensure your saw runs smoothly and lasts for years.

Tips for Central Machinery Band Saw Users

Here are some expert tips for maintaining and using your Central Machinery band saw safely and efficiently:

- Always use the correct blade for the material you are cutting. A blade with a coarser tooth count is better for cutting hardwoods or materials with a rough finish. A blade with a finer tooth count is best for cutting softer materials or materials you want a smoother finish on.

- Ensure the blade is properly tensioned. If the blade is too loose, it may sag and wobble, resulting in inaccurate cuts. A blade that is too tight can be difficult to install and may break.

- Keep the table and fence clean and free of dust and debris. This will help your saw run smoothly and prevent any accidents.

- Never force the blade through wood. This can damage the blade and lead to injuries. If the blade is not cutting through the material easily, use a higher blade speed, a sharper blade, or a blade designed for cutting thicker material.

Central Machinery Band Saw Parts: Frequently Asked Questions

Q: What are the most common reasons why a Central Machinery band saw might not be cutting straight?

A: A band saw that isn’t cutting straight can be due to several reasons. The blade might be misaligned, the guides might need adjustment, or the tension on the blade might be off. Also, a dull blade can lead to inaccurate cuts.

Q: What are some common Central Machinery band saw parts that need to be replaced regularly?

A: Some parts are prone to wear and tear. The band saw blade, of course, will need to be replaced when it gets dull or damaged. The bearings and guides should also be inspected and replaced if they show signs of wear. The belts can also crack or stretch over time and need to be replaced.

Q: What is the best way to clean my Central Machinery band saw?

A: Regularly cleaning your saw is essential for its longevity. Use a soft cloth or brush to remove dust and debris from the table, fence, and guides. Use compressed air to blow out any remaining debris, and be sure to lubricate the bearings according to the manufacturer’s instructions.

Conclusion

Understanding the components and functions of your Central Machinery band saw is key to getting the most out of your machine. From the blade to the guides, each part plays a crucial role in delivering accurate and efficient cuts. By mastering the basics of maintenance and understanding how to adjust and upgrade your saw, you can ensure it continues to serve you for years to come.

Central Machinery Band Saw Parts Diagram

Are you interested in learning more about Central Machinery band saw parts and how to make the most of your machine? Please leave a comment below, and we can discuss your specific questions!