Have you ever gazed at a welding blueprint and felt a wave of confusion wash over you? It’s a common feeling, but don’t worry! Though they might look like cryptic maps from another planet, welding blueprints are designed to be your guide, your roadmap to creating strong, precise, and expertly crafted metal structures. Understanding the language of welding blueprints unlocks a world of opportunity, transforming you from a skilled welder into a true master of your craft.

Image: www.studocu.com

This article serves as your comprehensive companion to the esteemed Blueprint Reading for Welders 9th Edition. We’ll delve into the fundamental elements of these blueprints, explore the importance of each symbol, and illustrate how to translate those lines and numbers into concrete actions in the welding shop. By the end of this journey, you’ll be equipped to confidently interpret any blueprint, whether it’s for a simple pipe joint or a complex industrial machine component.

Deciphering the Language of Welders

Think of a welding blueprint as a specialized language, one that uses lines, symbols, and numbers to communicate precise fabrication instructions. It’s a language that every welder needs to understand, regardless of their experience level. Here’s a breakdown of the key components you will encounter:

1. Views and Projections

A blueprint is more than a flat drawing; it’s a multi-dimensional representation of a component. You’ll typically see multiple views, such as front, side, and top, which provide a comprehensive understanding of the object’s shape and dimensions. The most important aspect of understanding these views is learning how they relate to one another, as the overall design is pieced together from multiple angles.

Think of it like building a model with Lego blocks. If you only have one side of the block, you can’t build the entire structure correctly. You need to see all sides to understand how everything goes together.

2. Lines and Symbols

Lines are the backbone of any welding blueprint. Each type of line has a specific meaning, guiding the welder through the construction process:

- Object Lines: These solid lines define the outline and shape of the object, giving you a clear picture of what you’re working with.

- Hidden Lines: You might encounter dashed lines that indicate features that are hidden from the current view but are still important to note.

- Center Lines: Thin lines with alternating long and short dashes, center lines show the midpoint of symmetrical features.

- Dimension Lines: These lines show the exact measurements of the component, critical for ensuring proper fit and welding accuracy.

- Weld Symbols: This is where things get exciting! Welding symbols are your roadmap, indicating where to apply the weld, what type of weld to use, and the size of the weld bead.

Remember, lines and symbols are not just visual elements; they are your guide, your blueprint, for creating the object accurately.

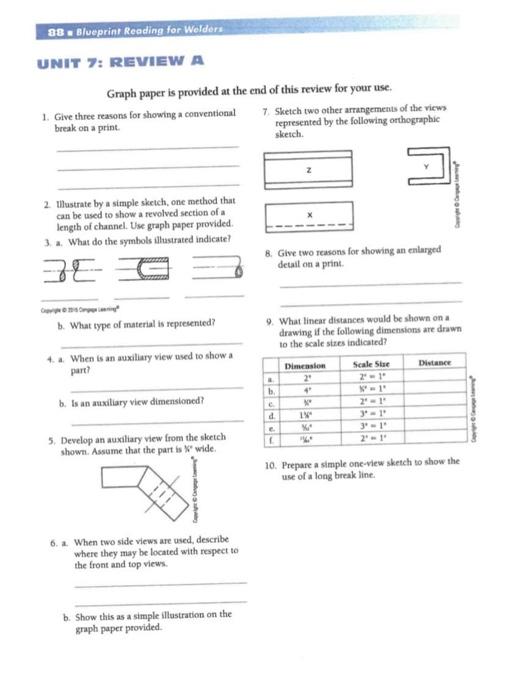

Image: www.chegg.com

3. Understanding Weld Symbols

Weld symbols are the heart of blueprint reading for welders. They provide you with the essential information about how the weld should be made. The 9th edition of Blueprint Reading for Welders has a comprehensive chapter dedicated to these symbols, breaking them down into their components and explaining their meaning.

Here’s a quick introduction:

- Arrow Side: The arrow points to the side of the joint where the weld is to be applied. Make sure you understand the direction the arrow is pointing as this determines which side of the joint faces the weld.

- Reference Line: This line runs perpendicular to the arrow and helps you locate the weld on the component. It’s a fixed reference point, guiding your placement of the weld.

- Weld Symbol: This icon is the key to understanding the specific type of weld required. There are standard symbols for various welding techniques, such as fillet welds, groove welds, and spot welds. You will learn these symbols in the book, effectively building a welding symbol dictionary.

- Dimensions: Numbers associated with the weld symbol provide vital information about the size and length of the weld. These numbers are crucial for ensuring the weld is strong enough to meet the structural requirements of the component.

- Supplementary Symbols: These are small icons that appear near the weld symbol, providing additional details about the weld. This can include information about specific weld processes, like backing, or the type of welding torch required. These supplementary symbols often provide crucial information for the welder to follow.

Remember, a slight misinterpretation of these symbols could lead to improper welds and potentially compromise structural integrity. The 9th edition of the Blueprint Reading text provides detailed explanations and diagrams to help you master these symbols.

Going Beyond the Basics

While the 9th edition guides you through the fundamental elements of blueprint reading, it also delves into more intricate concepts. Here are a few areas to explore:

1. Advanced Welding Techniques

Beyond the basic weld symbols, the book covers a wide range of advanced welding techniques. You’ll discover variations like:

- Single-Pass Welds: Creating strong and efficient welds with a single pass of the welding torch.

- Multi-Pass Welds: Building complex welds with multiple layers, allowing for greater control and strength.

- Overlay Welds: Adding material layers, often with a different metal, to enhance a component’s properties like hardness or corrosion resistance.

The book also discusses advanced welding processes such as:

- TIG (Gas Tungsten Arc Welding): Known for its precision and control over material, TIG welding is often utilized in applications requiring a clean and consistent weld.

- MIG (Gas Metal Arc Welding): This process offers a high deposition rate and suitable for welding thicker metals.

- SAW (Submerged Arc Welding): ideal for heavy duty applications, such as shipbuilding, where high speed and efficiency are critical.

The book provides step-by-step explanations and illustrations of these advanced techniques, allowing you to apply them confidently in your work.

2. Material Specifications

Welding blueprints often contain information about the specific materials used in the component. Blueprint Reading for Welders 9th Edition will guide you through understanding material specifications:

- Material Identification: Learning how to decipher material codes and symbols is critical for selecting the right welding process and consumables.

- Mechanical Properties: Welding blueprints may indicate the tensile strength, yield strength, and ductility of the materials, all factors vital to ensuring the structural integrity of the final product.

- Welding Process: The blueprint will specify the welding process, whether it’s MIG, TIG, or other methods, which ensures the chosen process is compatible with the materials used.

Understanding the impact of materials on welding is critical for producing high-quality, reliable welds. The book will equip you with the knowledge to interpret material specifications and make informed decisions about welding techniques.

3. Quality Control and Inspection

Ensuring the quality of your weld is crucial. Blueprint Reading for Welders 9th Edition introduces you to the world of welding inspection:

- Visual Inspection: This is an essential first step in verifying the quality of a weld. The book will teach you the signs of a good weld and the potential defects to watch out for.

- Non-Destructive Testing (NDT): This involves using techniques like radiographic testing or ultrasonic testing to identify internal weld defects that might not be visible with the naked eye. These tests play a crucial role in ensuring the safety and reliability of welded structures.

- Documentation and Reporting: The book covers the importance of documenting weld inspections, including documenting any defects found and the corrective measures taken. This ensures traceability and accountability for the quality of your work.

These quality control measures are crucial for ensuring the reliability and safety of welded structures. A robust understanding of welding inspection helps you to produce high-quality welds that meet industry standards.

Blueprint Reading For Welders 9th Edition Answer Key

Embracing Mastery

Mastering blueprint reading is not just about memorizing symbols and terms. It’s about developing a deep understanding of how the components fit together, how the welding process impacts the finished product, and how to ensure the quality of your work.

The 9th edition of Blueprint Reading for Welders serves as your guide and companion on this journey. By putting the knowledge you gain into practice, you’ll become a more confident and skilled welder. You’ll be able to tackle more complex blueprints, embrace new challenges, and contribute to projects that require intricate welding expertise.

If you’re looking to enhance your welding career, this book is a valuable resource. Start your journey today and witness the transformation in your understanding of welding blueprints! Remember, the language of welding blueprints is a key to unlocking your full potential as a skilled craftsman.